+91-9223503903, +91-8850827316

info@progressiveengineers.net

| Business Type | Supplier, Trader, Distributor |

| Shelf Life | 1 Year |

| Quality | Best |

| Storage | Store in a Cool Place |

| Click to view more | |

Product Details

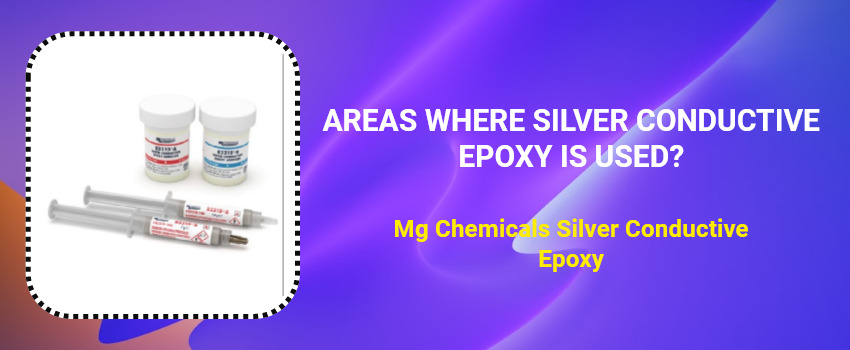

We are a distinguished Supplier of Silver Conductive Epoxy (8330S). The 8330S Silver Conductive Epoxy Adhesive is an electronic grade epoxy that combines a long working time and high conductivity with ease of use. It has a convenient 1-to-1 mix ratio and 45 hours pot life, which once mixed behaves essentially like a 1-part adhesive for the duration of a work shift. However, unlike 1-part adhesives that often require high heat (130170oC), it will cure at 65oC in less than 2 hours. The cured conductive adhesive bonds very well to most of the substrates used in electronic assemblies. It resists thermal and mechanical shocks and provides the low-resistivity needed for many operating conditions. The 8330S epoxy adhesive forms excellent high-conductivity seals, bonds, and traces for electronic devices in the automobile, aerospace, marine, communication, and industrial control.

Features :

- Excellent 0.0007 cm electrical resistivity and 1.75 W/(m·K) thermal conductivity

- Easy 1:1 mix ratio and long working time may be mixed once and then used as a 1-part epoxy for a four-hour production shift

- Optimal cure temperature of only 65oC lower than most 1-part epoxies and suitable for use on heat sensitive components

- Stores and ships at room temperature no freezing or dry ice required

- Very long shelf life of at least two years even when stored at room temperature

- Strong water and chemical resistance to brine, acids, bases, and aliphatic hydrocarbons

- Room temperature cure is possible (96 hours)

- Excellent adhesion to most electronic substrates

Applications :

- The 8330S epoxy has many uses in the production, repair, and assembly of electronics in microelectronics and optoelectronics.

- It has been designed for the production environments as a replacement for one part silver conductive epoxy systems when high cure temperatures can potentially damage the heat-sensitive components or where frozen storage requirements or shelf life of one part epoxies are a concern.

- Like all conductive epoxies, it operates as a lead-free replacement for metal solder and it excels at bonding heat-sensitive electronic components.

- It also provides excellent EMI/RFI shielding and is very effective in filling seams between the metal plates.

Application Instructions : Follow the procedure below for best results. Heat cure is recommended to get the best possible conductivity.

To prepare 1:1 (A:B) epoxy Mixture :

- Remove cap or cover.

- Measure one part by volume of A.

- Measure one part by volume of B.

- Thoroughly mix the parts together with a stir stick until homogeneous.

- Apply to with an appropriate sized stick for the application area.

Note :

- Remember to recap the syringe or container promptly after use.

- Tip - Due to the high viscosity and abrasiveness of the silver filler, you may preheat part A and part B to increase the flow and improve air release.

To Heat Cure the 8330S Epoxy :

- Put in oven at 65oC [149oF] for 60 minutes or above. For optimum conductivity and faster cure, heat cure at temperatures up to 100oC.

- Tip - Hair dryers are normally rated not to exceed 60oC, so they can generally be used to accelerate the cure.

- You can cure the epoxy faster by using higher temperatures of up to 100oC [212oF].

- Keep the curing temperature well below temperature limit of heat sensitive components that may be present. As a guideline, remember that commercial grade devices normally can be safely operated up to 70oC, industrial grade up to 85oC, and military grade up to 175oC.

- Attention - Heat guns can easily exceed the temperature limits for your assembly: they should not be used.

- To room temperature cure the 8330S epoxy:

- Let it stand for 96 hours or more.

- Tip - While the product can be cured at room temperature, the best conductivity is achieved with the application of some heat.

Available Sizes

| Catalog Number | Sizes Available | Description |

| 8330S-21G | 21 g (6 mL) | Paste |

| 8330S-50ML | 173 g (50 mL) | Paste |

| 8330S-200ML | 692 g (500 mL) | Paste |

Looking for "Silver Conductive Epoxy (8330S) Potting Compound" ?

Explore More Products

Our Blogs